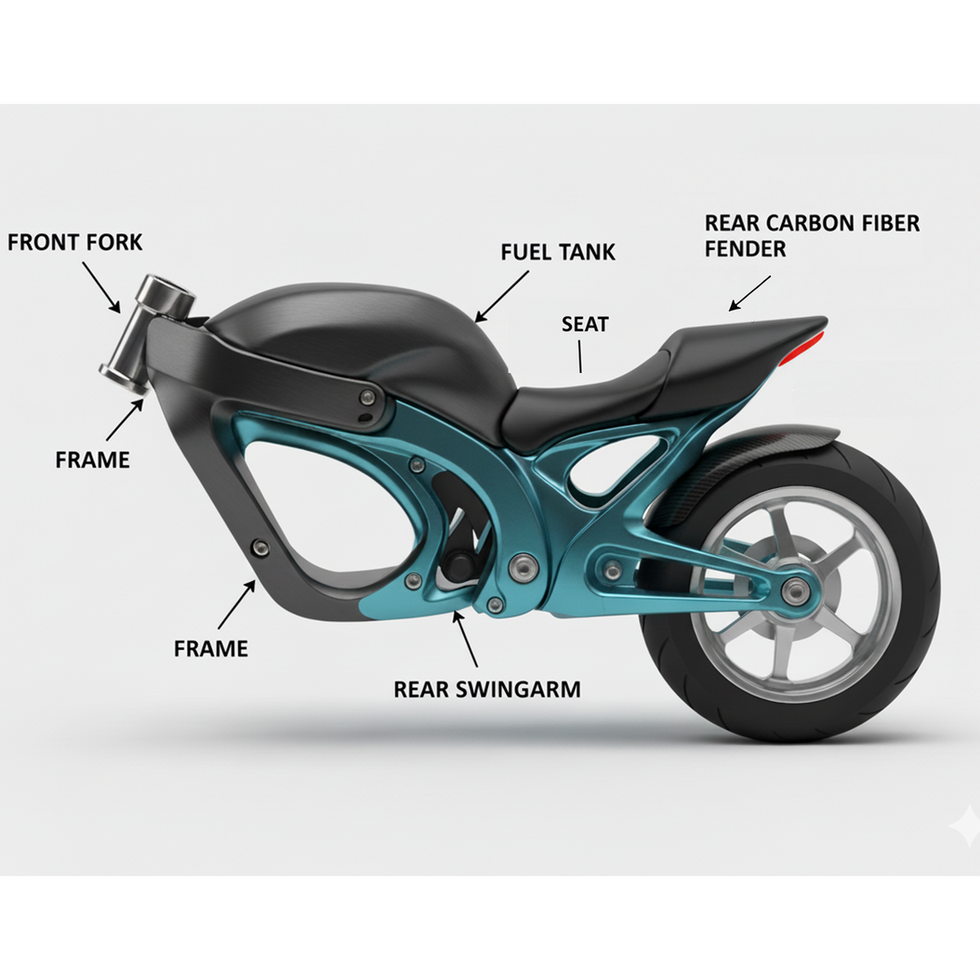

A concept motorcycle developed through a hybrid manufacturing process that combines 3D printing, composite layup, and polyurethane casting.

The project showcases the innovative integration of Massivit 3D technologies in advanced design and manufacturing for the automotive and composite industries.

The Hybrid Manufacturing Motorcycle Concept presents a hybrid production process that combines 3D printing, composite materials, and polyurethane casting serving as an applied study of advanced manufacturing methods.

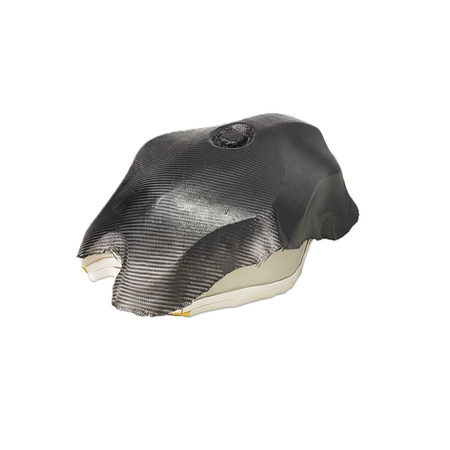

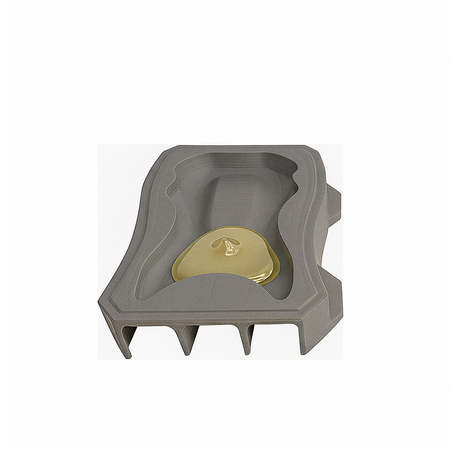

The motorcycle’s body was produced using various Massivit 3D technologies, enabling the integration of hollow structures, water-soluble molds, and precise functional components.

The fuel tank and rear carbon-fiber wing were fabricated using dissolvable molds layered with carbon fabric, while the seat was cast from flexible polyurethane within two 3D-printed epoxy molds.

The project demonstrates the potential of combining advanced additive manufacturing technologies with composite materials an approach that promotes design innovation and engineering efficiency within the automotive industry.